Henan Aifite Intelligent Equipment Co., LTD.

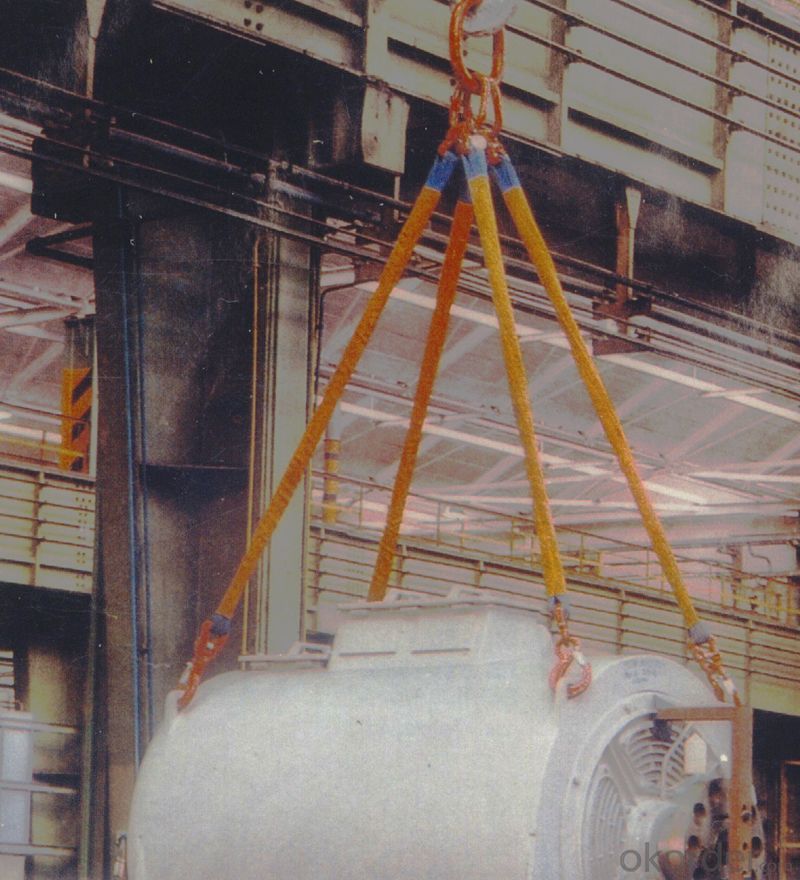

Crane Lifting Belt with Hook

Classification:

Product Introduction

Crane Lifting Belt with Hook

Lifting belt with hooks are commonly used tools for lifting operations. They are composed of flexible slings and hooks. They use the load-bearing capacity of the slings and the hook's hooking function to lift heavy objects in factories, docks, and other scenes.

It is usually made of high-strength synthetic fiber. Compared with traditional steel wire ropes, it has the advantages of light weight, softness, no damage to the suspended objects, and corrosion resistance. It is widely used in lifting operations in various industries such as ports, mines, and machinery manufacturing.

To determine whether the lifting belt needs to be replaced, you can start from the following aspects: Appearance and structural inspection

• Wear and damage:

◦ If the sling has a transverse edge cut, the body is cut, severely scratched, the belt strands are loose, or partially broken, it should be scrapped and replaced. For example, if the edge is cut by a sharp object with a clear notch, it needs to be replaced. ◦ Severe surface wear, wear reaches 1/10 of the original width of the lifting belt, or there are protrusions, penetration, tearing, scratches, and abnormal wear, it should be scrapped.

◦ If the thread ends are broken and detached, the loose thread ends may cause the entire sling to loosen and need to be replaced.

• Deformation:

◦ Severe twisting, deformation, and fuzzing. If the sling is twisted to a large extent and cannot return to its normal shape, it should be scrapped.

◦ The width is partially increased or decreased, and the structure has changed, so it needs to be scrapped.

◦ The appearance of a dead knot will affect the force and strength of the sling and needs to be replaced.

• Aging: The synthetic fiber softens or ages (yellowing), the surface is rough, the synthetic fiber peels off, the elasticity changes, and the strength is weakened, so it should be scrapped. If the sling is originally soft and elastic, but becomes stiff and brittle, it needs to be replaced.

• Chemical damage: mold and deterioration, acid and alkali burns, heat melting or scorching, looseness and corrosion in many places on the surface. For example, after the sling comes into contact with strong acids and alkalis, the material is corroded and should be scrapped.

• Warning lines and markings: Slings with red warning lines, the warning lines are exposed; the labels on the slings (rated load, production date, model, etc.) are blurred or missing, making it difficult to identify and determine the rated lifting capacity, and should be scrapped.

Keyword:

Feedback

Leave a message online and get the product quotation free of charge. We will arrange the specialist to contact you as soon as possible.